As a dental professional we know that you know that endodontics is a branch of dentistry that deals with saving infected teeth from being extracted by diagnosing, treating, and preventing dental pulp and root canal issues. Over the course of a career in dentistry, you will probably see hundreds of endodontic treatments – if not more.

With so many people requiring endodontic treatments, it is vital that you can provide excellent care for your patients.

To make sure that you are offering the best endodontic treatment possible, you need to have the right products. This is where Henry Schein can help. We've got a whole range of products covering the entire workflow, from files to sealers, and multiple obturation techniques. Everything you need to get the job done.

Let’s take a step-by-step view of the endodontic workflow and see how we can help you achieve the best outcomes for your patients.

Diagnosis

The initial step in the endodontic process involves diagnosis of the issue. Typically, patients report pain or discomfort in a specific tooth or region, prompting a comprehensive examination by a dentist. During this process, the dentist must establish whether an endodontic procedure is indicated.

Various diagnostic tools and techniques are employed to assess the tooth and the surrounding structures, allowing for the identification of the underlying cause. This crucial step enables the development of an appropriate treatment plan, tailored to the individual patient's needs.

For reliable diagnosis, a radiograph is required. This can be carried out by the traditional use of an X-ray, or a CBCT in more complex cases. Henry Schein offers a full range of X-rays to meet your clinical needs on our equipment website.

Endofrost and a heated plugger can also be used to verify whether the patient has reversible or irreversible pulpitis.

Endofrost

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

Magnification

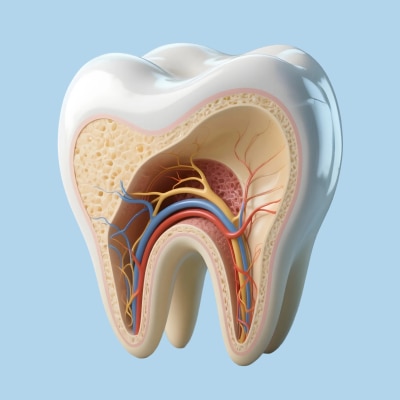

Successful Endodontic treatment relies on the ability to visualise the pulp and canals accurately. To achieve this, the use of a microscope is essential. At Henry Schein Equipment, have a range of microscopes, which offers exceptional crisp visualisation capabilities for endodontic procedures.

The microscope plays a crucial role in magnifying the operative field, allowing endodontists to have a detailed view of the tooth's internal structure. By providing enhanced visualisation, the microscope aids in locating and treating the root canal system effectively.

Shaping

Now that you’ve gained access, it's time to shape the canals in order to remove the pulp and any bacteria or debris from the root canals.

You will need to work carefully and thoroughly to make sure that you get all the pulp tissue out, leaving the canals clean and free from infection. By using a careful and thorough approach, you can ensure that the tooth is well-prepared for the next steps in the endodontic process.

For the best possible shaping, you want to have a range of files available for use, so that you have a suitable solution, no matter the canal shape.

The Endoflex k-file range is flexible enough to navigate anatomy, allowing you to create a sufficient glide path, or to apically gauge.

The files can also be used alongside the BA Optima motor with a built-in Apex Locator to allow you to accurately find out the working length.

For another solution for shaping, check out EdgeEndo’s products, which include a large range of heat-treated NiTi files complete with high cyclic fatigue and flexibility – perfect for shaping canals that have more complex anatomy.

Maxima paper points

A simple definition of CAD/CAM dentistry is the use of digital software to design and manufacture dental restorations and prostheses. CAD stands for computer-aided design and CAM stands for computer-aided manufacturing. The technology can be used to create crowns, dentures, inlays, onlays, bridges and veneers among other things. The speed of the CAD/CAM process allows for dental prosthetics to be designed, manufactured and delivered to the patient in quick time, sometimes the same day. The wider system of using computer assisted technologies to produce restorations is known as CEREC (Chairside Economical Restoration of Aesthetic Ceramics).

Obturating

The last step in the endodontic process involves filling the root canals with a biocompatible material, typically gutta-percha, a rubber-like substance. Specialised instruments are used to fill the canals with this material and then seal them with a temporary filling until a permanent restoration, such as a crown, can be placed on the tooth.

It is vital that the filling material is inserted correctly and that the tooth is sealed effectively, as it is essential for the success and longevity of the treatment.

EdgeEndo and Endosequence have a great choice of Gutta Percha points for cold obturation, which can be ideal when used alongside a Biocereamic sealer.

EdgeCore and EdgeFill, which can be used for heated obturation, allow for easy placement and removal, and dense 3D obturation. As well as all this, EdgeCore is compatible with canals that have been shaped by any popular files, not just EdgeEndo offerings.

Alternatively, Henry Schein’s own range of gutta-percha points are flexible and reliable, creating a protective layer over the canal that keeps bacteria and debris from interfering. The gutta-percha material is biocompatible, so you know it’s safe to leave inside the tooth.